The UV curing consists of the solidification of ink, varnish … by use of ultraviolet radiation emitting lamps on materials in the finishing process.

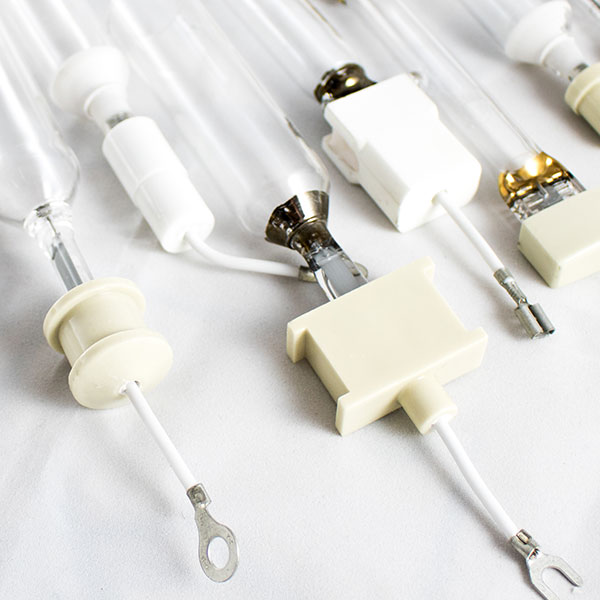

An UV lamp consists of a quartz glass bulb or tube filled with gas, with two electrodes at the ends, which by supplying electricity forms an arc between them, heating and increasing the pressure of this gas and producing light emission.

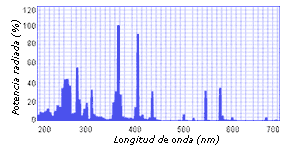

Depending on the gases and additives inside the bulb will result in a spectrum or another.

The UV curing lamps stand out for its versatility and functionality in every ultraviolet application, since this system does not involve the use of solvents. Its main use is the curing or drying of materials for polymerization and oxidation.

Variants and odds of the UV curing lamps

Sockets and endings of the bulbs

The caps of the UV lamps may be either ceramic or metallic, with or without wires, shaped as needed to take.

Power and dimensions

We can supply lamps with an arc length from 50 mm up to 2 meters long, and power from 80 W/cm to 600 W/cm (according process needs).

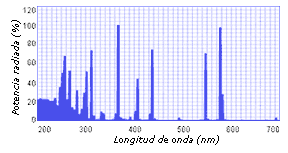

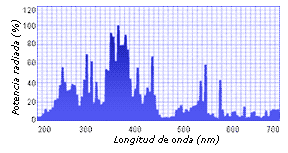

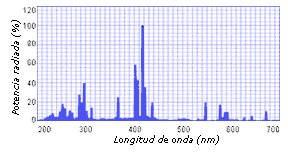

UV spectral distribution

UV lamps can be manufactured with different dopings depending on the ultraviolet emission that needs to be obtained. The most common is mercury vapor, but they are also doped with gallium, iron, lead … depending on the treatment to be performed and the desired spectrum.

We also supply germicidal lamps for UV disinfection, and all kinds of emitters and special bulbs for other uses.

Contact us without commitment and we will quote you the lamps you may need.