Description

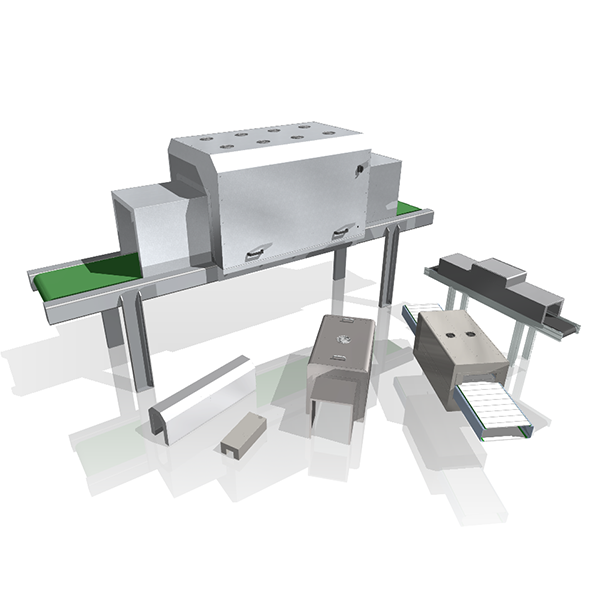

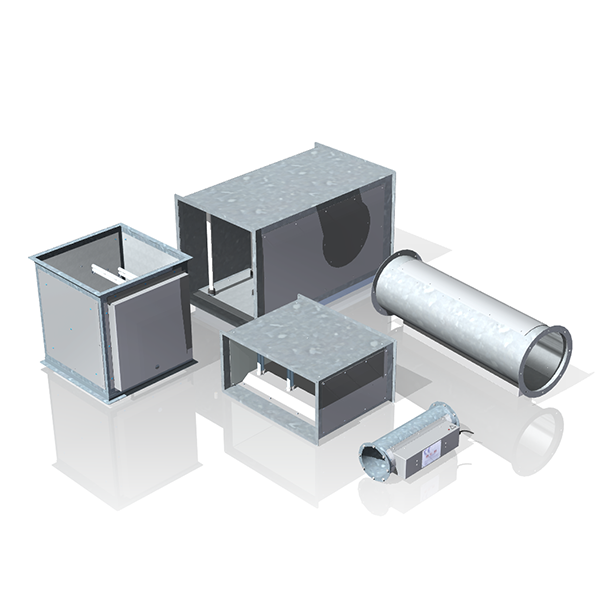

We can propose different types of UV reactors and ultraviolet sterilizers for water treatment depending on the type of water, the flow to be treated and the use to which it is intended.

Each field of application has its ideal ultraviolet reactor, whether for swimming pools, spas, aquariums, thalassotherapy, well extraction or municipal potabilization. We also have UV sterilizers for industrial and pharmaceutical processes such as membrane treatment systems, destruction of residual ozone, oxidation processes of pollutants, etc.

UV disinfection systems disinfect water by eliminating microorganisms without the need for chemicals. They also allow its dechlorination (in each recirculation the level of chlorine is considerably reduced).

Regarding the dimensioning of the reactors and ultraviolet sterilizers, this is done according to the requirements of the water and its status. Consult us and we will make you study and an economic offer quickly.

Characteristics of UV reactors:

- Structure made of stainless steel or PEHD polyethylene (for salty or corrosive waters)

- Variable flow from 0.5 to >600 m³/hour

- Minimum yield per flow: 33 mJ/cm² (depending on the type of water)

- UV emission and optimized hydraulic flow.

- Electronic ballasts and integrated control or autonomous electrical cabinet.

- Equipped with high output UV lamps or long-lasting amalgam bulbs (~12000/13000 hours of life)

- Number and power of lamps variable according to needs.

- Connection and customizable flanges.

- Purge plug and fixing feet.

- Very simple and intuitive operation and control from touch screen or keypad.

- Loss of insignificant load.

Optional:

- Digital time counter with reset.

- UV sensor and monitor with alarm for information collection.

- Internal cleaning device without disassembly, with manual or automatic operation.

- …